Servicing

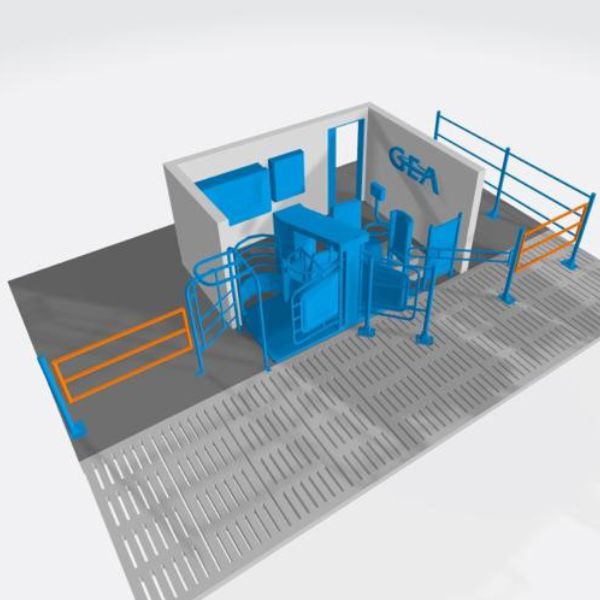

Parlour Servicing

At Dairyflow we offer a complete aftercare and yearly service plan on all GEA Farm Technologies equipment which is carried out by our two MEA qualified technician's.

Milking systems are designed to work efficiently throughout their lifetime. They should maximise milk yields and minimise milking times and above all do this in a manner which does not impair the cow's teat condition and udder health. Our aim is to support your profitability by maximising your yields of high-quality milk and minimising your costs of production.

Regular maintenance

To ensure the milking machine continues to function efficiently it must be maintained in accordance with the manufacturer's recommendations. This includes routine checks by the farmer as well as scheduled servicing by the dairy engineer to replace worn components. It is a requirement for National Dairy Farm assurance standards and is there to protect the interest of the producer and their cows as well as the consumer.

Plant testing

Parlour testing is performed by trained and qualified dairy engineers. Tests can be "static" performed between milking's or "dynamic" conducted during milking.

Why test?

To prevent breakdowns that interrupts farmer and cow routines and cost time.

To avoid less obvious faults that may reduce milking efficiency, affect milk yield and quality, and at worst create conditions that encourage mastitis.

As with service, regular preventative testing ensures that the equipment is optimized, enabling you to stay ahead of most problems and to "nip them in the bud" before they take effect and increase your costs.

Call us today on 01563 532111 to discuss your parlour servicing and testing requirements or send us an email scott.baird@gea.com