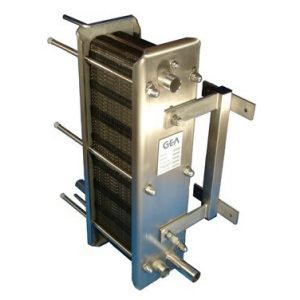

TCool Cooling Tank

The key characteristics of the milk tank at a glance:

- The milk tank is available in 24 variants: a large selection for customized milk cooling

- Milk tank with top-quality insulation

- Individually configured milk intake: With inlet from above, from below, front the front and from the back

- Long-lasting evaporators: high reliability of milk storage thanks to constant quality control.

The efficiency with which you are able to cool and store the milk becomes obvious when you look at the statistics. The TCool milk tank prevents the formation of thermal bridges and limits the temperature increase to 0.5°C in a period of 12 hours.

Storing and cooling milk: as individual as never before with the GEA milk tank

Description

The storage of milk is a very important factor in dairy farming. Only by cooling the milk can the quality be fully maintained. The GEA solution: the TCool milk tank with horizontal storage.

The key characteristics of the milk tank at a glance:

- The milk tank is available in 24 variants: a large selection for customized milk cooling

- Milk tank with top-quality insulation

- Individually configured milk intake: With inlet from above, from below, front the front and from the back

- Long-lasting evaporators: high reliability of milk storage thanks to constant quality control.

The efficiency with which you are able to cool and store the milk becomes obvious when you look at the statistics. The TCool milk tank prevents the formation of thermal bridges and limits the temperature increase to 0.5°C in a period of 12 hours.

Storing and cooling milk: as individual as never before with the GEA milk tank

You can cool your milk with the TCool milk tank using a total of 24 different variants and capacities – from 1,010 up to 33,500 litres. The advantages:

- Cooling milk: You save energy with the milk tank

- The tank can be efficiently cleaned

- Easy to operate ICool control system

Monitor and control every parameter with the ICool control system. This milk control system enables you to achieve an accuracy level of +/- 0.2 % at 4 °C. The ICool control system can also monitor your energy consumption fully automatically, alerting you to any errors that may occur in the cold chain.

Storing milk: excellent cleaning for milk production

Regardless of which tank you decide on: A complete drainage at the end of the cleaning process is possible with a vertical high-performance pump to prevent the milk from freezing which could impair the milk quality. An intake filter on the pump prevents the spray head from clogging and additionally protects the pump.

The general dosage of the cleaning agent is carried out using the pump. This prevents direct contact with the cleaning agents and offers the additional advantage of precisely regulated quantities. The ICool control system handles changes to the cleaning agent, which saves you time and prevents contact with powerful cleaning agents which could be hazardous to your health. When storing and cooling milk several forms of contamination can occur, making the use of various cleaning processes necessary.

Choose between alkaline and acidic cleaners. If desired, disinfection using a third pump is also possible

Cool and store milk, and store the most important data

Get the most out of your ICool control system with ICool Analyzer. Your benefits: ICool Analyzer gives you easy access to status information for up to 4 cooling units and the agitation process. The software also now provides an option to record comprehensive volume and temperature profile information. With ICool Analyzer, you can access the last 100 washing cycles directly from the display, and archive up to 10 years’ worth of data onto a USB stick. The data can also be exported as a CSV file for further analysis in Excel.

Reviews

There are no reviews yet.