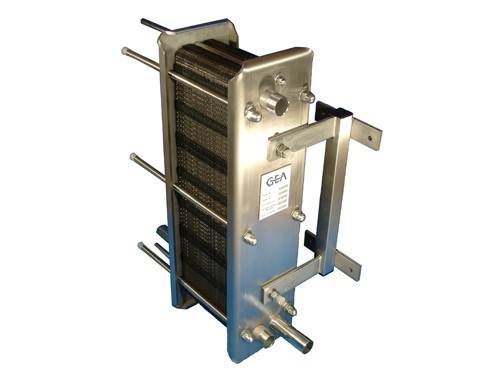

Plate Cooler

For lower production costs and improved milk quality

Reduces the energy requirement for cooling milk

- Rapid cooling suppresses bacterial growth

- Designed to handle output from fast throughput milking parlours

- High quality stainless steel construction provides hygienic surfaces inside and out as well as durability

The plate cooler is an essential part of any cooling system. Rapid reduction in milk temperature protects milk quality by suppressing bacterial growth. Dramatic savings in electricity and compressor wear and tear ensure optimum performance at all times.

Description

For lower production costs and improved milk quality

Reduces the energy requirement for cooling milk

- Rapid cooling suppresses bacterial growth

- Designed to handle output from fast throughput milking parlours

- High quality stainless steel construction provides hygienic surfaces inside and out as well as durability

The plate cooler is an essential part of any cooling system. Rapid reduction in milk temperature protects milk quality by suppressing bacterial growth. Dramatic savings in electricity and compressor wear and tear ensure optimum performance at all times.

A single-bank plate cooler consists of a series of stainless steel plates. Warm milk flows through alternate plates in one direction whilst cold water flows through the remaining plates in the opposite direction removing heat from the milk. A double bank plate cooler has two sets of plates, so the milk and water pass through twice thus improving the efficiency of heat exchange. A correctly-sized plate cooler will reduce the temperature of the milk to a-b°C (single-bank) or c-d°C (double bank).

There are a number of options for using the residual warm water from the plate cooler. For example, it may be used as part of a heat recovery system for heating wash water, for pre-rinsing the milking equipment, or for washing down the parlour at the end of milking.

The GEA Farm Technologies plate cooler leads the way in milk cooling technology. High capacity plates that are 50% larger than the normal size maximise the area of the cooling surface and minimise the pressure drop.

40mm milk inlets/ outlets and 11⁄2” BSP water inlets/outlets ensure unrestricted flow through the plate cooler. A complete stainless steel construction prevents rusting of frame and provides longevity.